Return Elbow Bender

Led Bulb Housing

Yellow Pu Sheet

Lighting Pole

Bending Tester

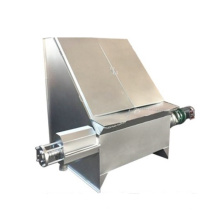

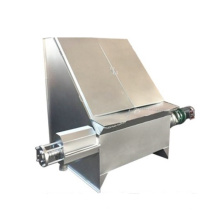

Butyl Extruder Insulating Glass Machine

Pipe Bending Machine

Hydraulic Press Brake

Drum Screen&Mechanical Filter

Down acting hybrid cnc press brake

Model NO.: sheet metal parts Company Type: Factory Transport Package: 1.PE-Bag/Carton-Box/ Pallet, Customize Package Ava Origin: China Model NO.: sheet metal parts Company Type: Factory Transport...

Owing to its quality and competitive pricing, Hydraulic Bending Machine is highly preferred. The offered machine finds its application in several

industries for the purpose of reinforcing and bending bars to various shapes and forms. The machine`s easy installation and operation minimizes the

using of labors. The offered product is highly durable and economical as well.

· Most forms can be produced without extra tools on a bending machine · Continuous bending from straight to round without interruption on a folding machine · The bending machine can be operated by one person even if larger pieces are being produced · A Folding machine is easier on operator fatigue since the component rests flat on the machine bed during operation [as opposed to travelling up in the air] · Spring back behaviour of different metals and different thicknesses can easily being controlled on a folding machine · A fully automatic working cycle can be programmed · Full safety at all times · The folding machine is fitted with a clamping system, which holds the plate in position for better accuracy · Cutting errors will result only at the end of the profile on the last bend on a folding machine · Small variation in material thickness do not affect the bending angle on a folding machine · A skilled operator is not required as the whole cycle is automatic and managed by the CNC · Since virtually no changing of tools is required there is a substantial reduction in operating time on a folding machine · Accurate repeatability due to CNC and high resolution encoders · Cone and round bending processes are available on a folding machine · Box bending attachment is available on a folding machine · The installation of back gauges allow the use of handling devices such as gantry cranes and unloading tables, reducing the operator involvement · For processes, the like for like folding machine requires less power · Goat foot tools are easily installed and increase the possibility of complicated bends · Under present guarding regulations Light guards are not required which saves expense · A folding machine is more versatile and ready to bend any angle without first setting up tooling More Advantages